Critical Minerals and Energy Intelligence

Antimony

Antimony hit the steepest rally in price “ever recorded” in the global antimony market since April 2024, according to FastMarkets who began recording prices from January 1980.

Supply shortages, export restrictions from China, falling global supply, as well as rising demand across defense and solar, mean the short, medium and long-term trends for supply security are volatile.

Antimony Insights

Latest News

What is antimony

Antimony, atomic number 51, is a lustrous gray metalloid valued for its flame-retardant properties and use in various industrial applications. With a melting point of 630.63°C, it is a solid at room temperature and is often alloyed with other metals to enhance their hardness and resistance to corrosion.

The name “antimony” originates from the Greek words “anti monos,” meaning “not alone,” reflecting that it is typically found in nature combined with other elements.

Today, antimony is crucial in flame retardants, batteries, and alloys, securing its status as a critical mineral.

Why antimony matters: strategic applications

Flame retardants

Antimony trioxide is a primary flame retardant used in plastics, textiles, and rubber. It is often used synergistically with halogenated flame retardants to enhance their effectiveness.

plastics: antimony compounds are added to plastics in electronics and automobiles to prevent fires.

textiles: treated textiles are used in clothing and home furnishings to meet fire safety standards.

Batteries

Antimony is used in lead-acid batteries to improve their strength and corrosion resistance.

grid alloys: Antimony enhances the mechanical properties and lifespan of battery grids.

electric vehicles (EVs): although lithium-ion batteries dominate the EV market, antimony is used in some advanced battery technologies.

Alloys

Antimony is alloyed with other metals to improve their hardness, strength, and corrosion resistance.

Lead alloys: antimony hardens lead used in bullets, cable sheathing, and solder.

Bearing alloys: antimony is used in bearing materials for machinery due to its low friction and wear resistance.

Supply and Demand Dynamics

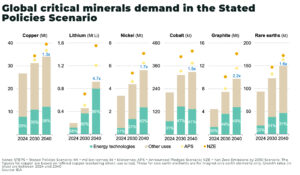

Global antimony demand is driven by flame retardants, battery production, and alloy manufacturing. Key demand drivers include:

flame retardants: regulations requiring flame retardancy in various products drive demand for antimony trioxide.

battery manufacturing: the automotive industry’s reliance on lead-acid batteries and emerging antimony-based batteries contributes to steady antimony consumption.

Supply Landscape

Production Concentration

Global antimony production is concentrated in a few countries, with China being the dominant producer:

China: the leading producer of antimony, accounting for a significant portion of global output.

Russia: a notable producer with significant reserves and production capacity.

Tajikistan: an emerging antimony producer with growing production.

This concentration creates supply chain vulnerabilities, making the diversification of supply sources important.

Mining Characteristics

primary and by-product mining: antimony is mined both as a primary product and as a by-product of other metals, such as lead and silver.

processing complexity: antimony ores require complex processing techniques to extract and refine the metal.

Major producers

The antimony mining sector features several key players:

China Molybdenum Co., Ltd. (CMOC): a major global mining company with significant antimony production.

Hunan Chenzhou Mining Group Co., Ltd.: a key Chinese antimony producer.

Market trends shaping antimony’s future

Supply chain security

diversification: efforts to diversify antimony supply chains are underway to reduce reliance on single-source countries.

strategic stockpiling: governments are considering strategic stockpiles to ensure a stable supply of antimony for critical applications.

Technological evolution

battery technology: research into advanced battery technologies using antimony could drive future demand.

recycling: developing efficient recycling processes for antimony-containing products can enhance supply security.

Regulatory environment

critical mineral designations: governments worldwide classify antimony as a critical mineral, incentivizing domestic production and supply chain development.

Antimony’s unique properties make it essential for various applications, particularly flame retardants and alloys. As industries prioritize supply chain security and technological advancements, antimony’s strategic importance will likely increase, making it a critical material for modern industrial society.

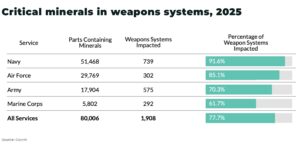

US launches $12 billion strategic minerals stockpile

The US will establish a US$12 billion strategic minerals stockpile, marking its most direct intervention yet in critical mineral markets as competition with China intensifies.

US-backed $7.4bn smelter escalates critical minerals decoupling from China

The US has thrown its weight behind a US$7.4bn critical minerals processing plant to be built by Korea Zinc, underscoring how refining and smelting —

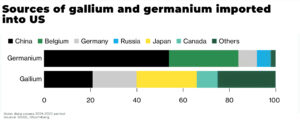

China lifts export ban gallium, germanium, antimony

China has suspended the export ban on gallium, germanium and antimony to US until November 27, 2026. Exports will now be managed under licensing until

US to build $1 billion critical mineral stockpile as supply risk deepens

The US Department of Defense is preparing to purchase $1 billion worth of critical minerals to build a national stockpile and shield military supply chains

Why the US fails to secure critical mineral supply — and how it can be fixed

An inside look into what’s gone wrong in Washington — and how to fix it In December 2024, China banned exports of gallium, germanium, and antimony

Is this the “shale moment” for critical mineral mining in the US?

A quiet revolution is underway in the bedrock of the global economy. The mining and processing of critical minerals — from lithium to rare earths,